Kepler Robotics Begins Delivery of K2 Humanoid: The 75kg "Bumblebee" Built for Factory Floors, With 30kg Dual-Arm Payload and 8-Hour Endurance

Category: Tool Dynamics

Excerpt:

Shanghai-based Kepler Robotics has started delivering its flagship K2 humanoid robot — nicknamed "Bumblebee" — following mass production kickoff in September 2025. Weighing 75kg with a dual-arm payload of 30kg (15kg per arm), it charges in one hour for up to eight hours of continuous operation. The first batches are heading to automotive manufacturing lines, where early tests show 1.5x human efficiency in material handling and assembly. With thousands of intent orders already secured, Kepler is accelerating China's push toward "humanoid factory workers" in the 2025 mass-production era.

🐝 Kepler K2 "Bumblebee": The Yellow Vanguard Invading Humanoid Robot Factories

The humanoid robot factory invasion just got a bright yellow vanguard. Kepler Robotics' K2 "Bumblebee" isn't waiting for perfect conditions — it's shipping now, straight from Shanghai's production lines into real-world industrial chaos. After ramping up mass production in September 2025 and securing framework agreements worth hundreds of millions of yuan, the company has begun phased deliveries, prioritizing automotive giants for tasks like parts transport, quality inspection, and line assembly.

This marks a brutal milestone in China's humanoid surge: a commercially viable bot that's not just demo-ready but deployment-proven, with self-developed actuators powering through shifts that would exhaust human workers.

🔧 Hardware That Hauls Like a Blue-Collar Beast

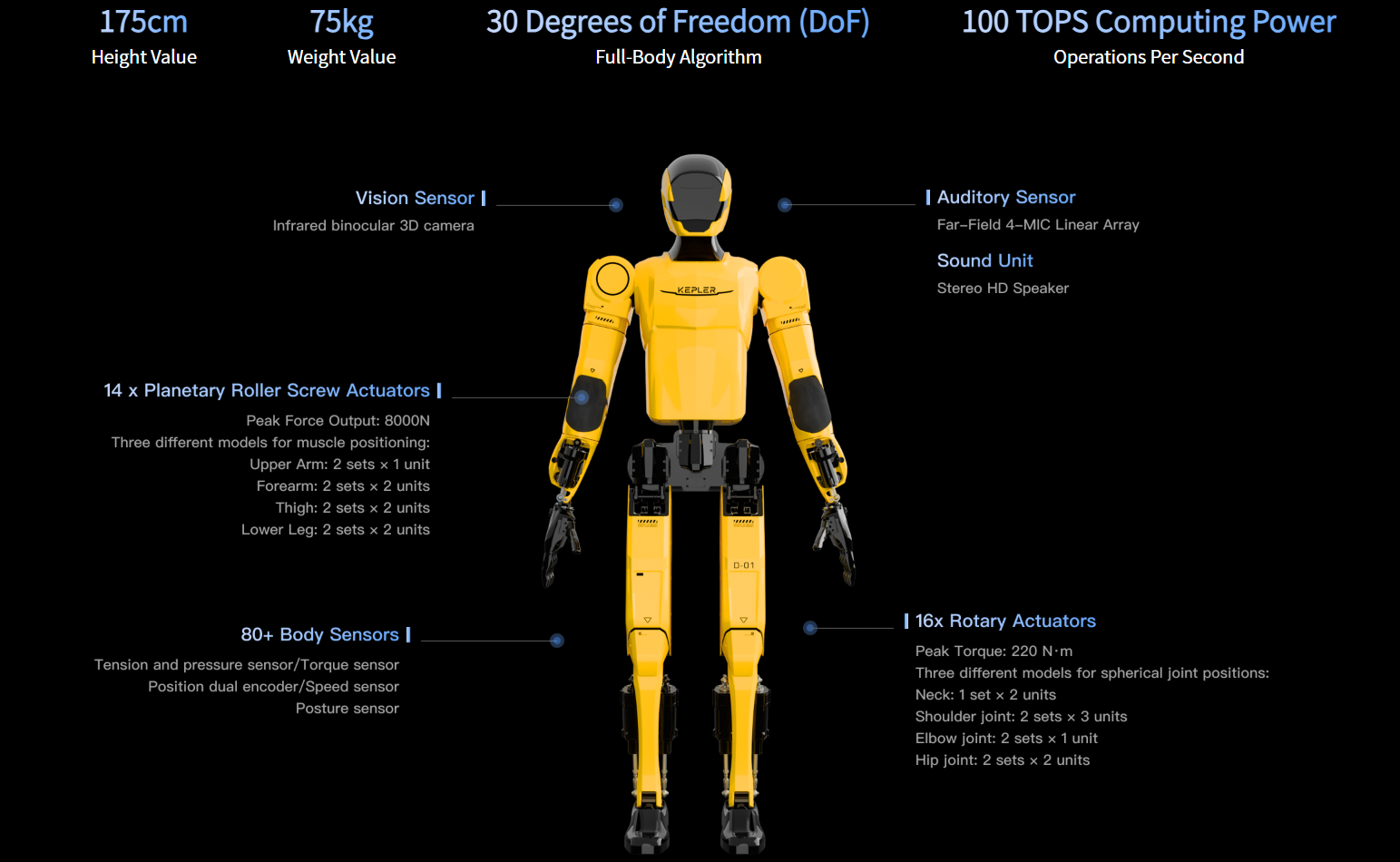

K2's specs are engineered for the grind, built to thrive in high-intensity industrial environments:

| Feature | Details |

|---|---|

| Robust Frame | 175cm tall, 75kg body optimized for stability in dynamic factory settings. |

| Powerhouse Arms | Dual-arm max 30kg payload (15kg per arm), driven by proprietary planetary roller screw actuators for millimeter-precision lifts without excessive power drain. |

| Endurance Edge | 1-hour charge delivers 8 full hours of operation — perfectly matching standard factory shift rhythms with zero downtime for mid-shift recharging. |

| Dexterous Details | 52 total degrees of freedom (DOF); 11 DOF per hand with tactile sensors (25 force points per finger); 80+ integrated sensors enabling seamless human-robot collaboration. |

| Hybrid Architecture | Series-parallel design balances performance and efficiency: dynamic bursts for heavy lifts, near-zero static consumption during holds. |

🖥️ Interface That's Factory-Floor Intuitive

Drop K2 into your production line via Kepler's OS dashboard — it auto-maps environments using pure vision navigation, then executes tasks through a powerful combo of cloud-brain and embodied cerebellum.

🚀 Real-Time Flexibility

- @K2 mid-task to tweak instructions: “@handle fragile components” or “@optimize path around forklift”

- Outputs sync seamlessly to ROS for fleet integration, with semantic versioning to roll back “risky maneuvers”

- Enterprise-grade perks: VPC isolation, custom gripper options, and seamless prototype-to-production scaling.

📊 Early Deployment Data: Efficiency on Steroids

K2’s real-world performance is already turning heads (and boosting bottom lines):

- Order Onslaught: Thousands of units pre-booked, with framework agreements valued at hundreds of millions of yuan. Early clients report 1.5–1.8 year ROI at ~$30K/unit pricing.

- Auto Sector Assault: First deployments target car plants (echoing Tesla Optimus’ ambitions), slashing handling times by 40%+ in material flow and quality inspection.

- Benchmark Bragging: Outperforms peers in payload-to-weight ratio and endurance; real-world tests show 3x fewer interventions than quasi-direct-drive rivals.

- Supply Chain Control: 80%+ self-developed core parts (roller screws, harmonic drives, dexterous hands) keep costs in check and supply chains resilient.

⚠️ The Fine Print: Scaling the Last Mile

While K2 is production-ready, beta realities include:

- Nascent complex multi-bot coordination capabilities

- Evolving robustness in extreme weather conditions

- Pending regulatory approvals for full autonomy in some regions

Kepler mitigates risks through geo-diverse testing and safety interlocks, while pros can integrate third-party AI for niche skills. Priced to penetrate (under million-yuan prototypes), K2 is built for volume — not perfection.

🌍 Industry Quake in the Making

This isn’t a lab escapee — it’s a calculated charge into the $10B+ humanoid robot market. While Tesla teases 2026 scaling and Figure refines finesse, Kepler’s delivery blitz (backed by investors like Tao Motor and Hanwei Tech) democratizes “blue-collar bots” for mid-tier factories.

Auto lines today, logistics tomorrow — Bumblebee’s buzz is turning intent into invoices, proving 2025’s “mass production year” isn’t hype; it’s happening in yellow.

Kepler’s K2 delivery isn’t just hardware hitting docks — it’s the tipping point where humanoids shift from spectacle to staple, replacing repetitive drudgery with tireless precision. As Bumblebee swarms factories, expect a productivity supernova: shorter cycles, safer lines, and a blueprint for global scaling.

China’s message? The humanoid workforce isn’t future tense — it’s present shift, and Kepler’s clocking in early.